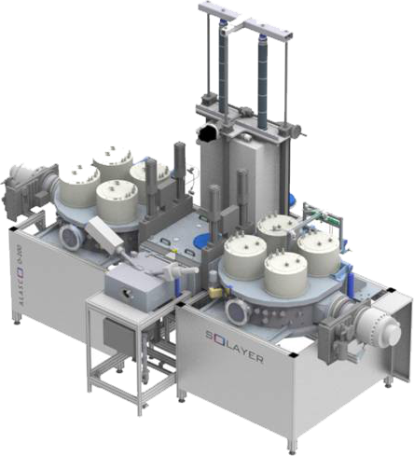

ALASCO O-200

Modular scalable cluster platform

Various coating technologies

Safe and reliable production

Outstanding flexibility

Ready for future applications

Versatile optical coating on up to 200 mm substrates

Offering more than sputtering, this modular configurable platform is ideal for R&D and production of high-end optical coatings.

We are aware that novel applications require novel production technologies, giving you the opportunity to apply cutting-edge coating designs. Solayer’s ALASCO O-200 is capable to combine various deposition technologies into one system. It is possible, for example, to combine various sputtering methods, evaporation, PECVD or ALD in one and the same coating run. Beside pulsed magnetron sputtering and HIPIMS, it also offers simultaneous co-sputtering for novel material mixtures. In addition, future-oriented technologies such as Plasma-Immersions-Ion-Implantation (PIII), Flash Lamp Annealing (FLA) modules and in-situ metrology for in-depth film analytics are available for customized tool configurations. These unique features allow material combinations not feasible with standard production equipment for optical coatings.

ALASCO O-200 is a modular configurable system concept that allows the extension of the tool with additional modules or exchanging modules to other process technologies at a later stage.

The cluster tool type system can be equipped with multi-substrate magazine to enable automatic processing of substrates with different process sequences. These could be flat substrates as well as thick shaped-substrates up to 200 mm in diameter.

The AVIOR O-200 is suited to work in a daily-changing R&D environment as well as in the demanding production environment for sophisticated high-precision optics.