Planning a new project? Talk to us!

Versatile Cluster Deposition Tool

Solayer's cluster tool is a fully automated deposition and analysis system that is used in R & D, pilot and small scale production. The system has a central distribution chamber and robot handler to process thin film layers based on PVD, PECVD, ALD, PLD, IBAD, XPS, XRF, AES, SPM, MOKE and FLA.

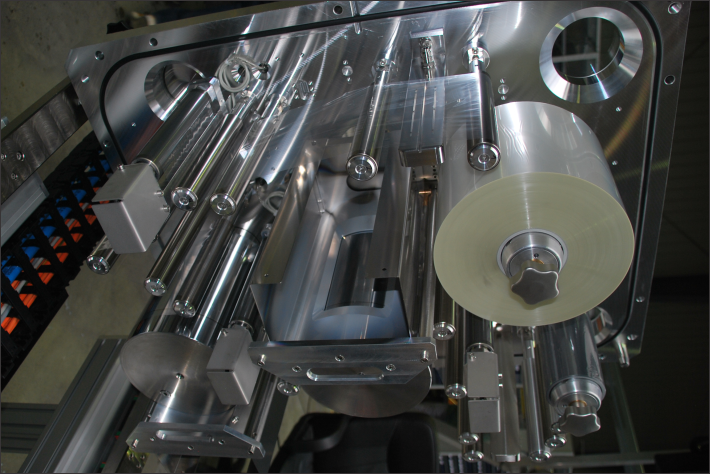

Roll-to-Roll Coater

The roll-to-roll (R2R) coater is a modular process design based on the sputtering of materials on flexible substrates - plastic / polymer foils or thin glass. The setup can be expanded to integrate ion beam / microwave pre-treatment and halogen lamp or flash lamp annealing (FLA).

Co-Sputter Cluster System

The magnetron-based deposition system features a co-sputter arrangement of up to 6 sputter sources in one / two chambers (independent DC or RF). With automatic loading and advanced angle / T-S position adjustment, the deposition of gradient or mixed layers opens a wide range of applications.

ALD Tool for Ultra-thin layers

The Atomic Layer Deposition (ALD) tool is a custom-built R2R equipment that offers high layer conformity at high aspect ratios as well as an exact control of the layer thickness. The tool is designed for advanced R&D-processes as well as for processes in an industrial scale.

High Precision Layer Equipment

The fully-customizable platform offers a unique combination of magnetron sputtering, evaporation and in-situ metrology. With capabilities to deposit layers on substrates of up to 200 mm in diameter, this small scale production tool is optimized for multi-layer treatment of lenses, mirrors, filters etc. Read more

Ion Implantation Tool

The Ion Implanter is a unique tool based on PBII technology to change or modify the surface properties of different materials, creating new phases and alloys, far away from the thermal equilibrium. It is based on a modular concept for ion implantation, doping and deposition processes.

Variety of substrate shapes and materials

Scalable for R & D, pilot and mass production