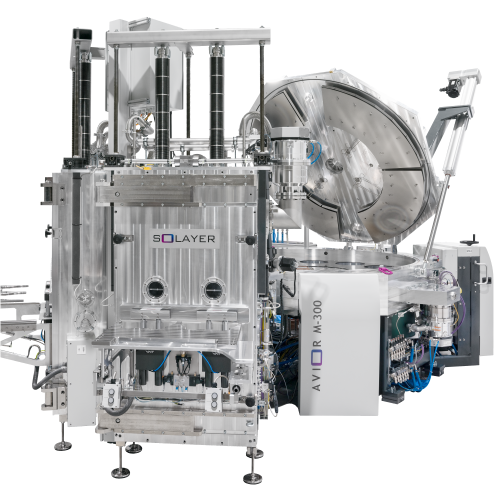

AVIOR M-300

Excellent Process Stability

Superior Film Quality

Outstanding Productivity

Unique Flexibility

Ready for future Demands

Ultra high-precision optical Coating Equipment for Emerging Technologies

In the light of the changing industry landscape generated by emerging technology device applications, SOLAYER GmbH offers a precision optical coating production tool engineered based on these tight technical requirements. Further innovations in the recent version of the AVIOR M-300 not only guarantees high throughput and reliable mass production of precision optics, but also keeps within the outperforming film characteristics such as uniformity, thermal stability and non-absorption to moisture.

The AVIOR M-300 is designed to produce sophisticated dielectric filters such as edge filters, bandpass and notch filters, as well as beam splitters and mirrors. Its market attraction stems from the ability to meet proprietary coating specifications for optical filters in consumer electronics, automotive sensors and telecommunication accessories. Recent developments on amorphous silicon (a-Si:H) layers have enabled a major advancement in the production of narrow bandpass filters for 3D-sensing applications.

Its’ novel combination of a sputter-up configuration with Dual Rotary Magnetrons offers unrivaled competitive benefits such as process stability, lowest particle count, minimal service time and cost of ownership. The AVIOR M-300 can accommodate as much as ‘12’ units of 300 mm substrates per run. Its’ flexibility in production owing to the carrier system gives it a fifty percent increase in throughput, relative to rival tools on the 200 mm substrate size.

Equipped with either an in-situ monochromatic or broadband optical monitoring system for deposition and film process monitoring-control, frequent calibration and test-runs, even for stack designs of several hundred layers can be avoided; leading to stable and predictable deposition processes for several weeks. Extremely dense and shift free layers can be deposited with layers that have almost no intrinsic roughness and a unique uniformity of down to ± 0.2 percent.