Upgrading your system components? Talk to us!

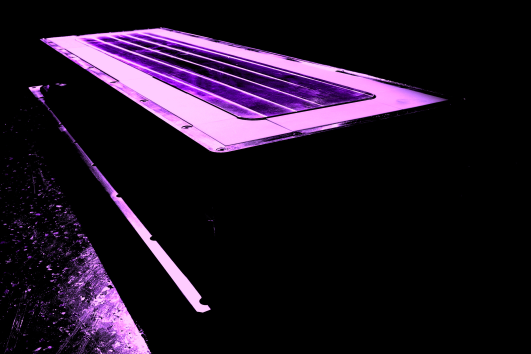

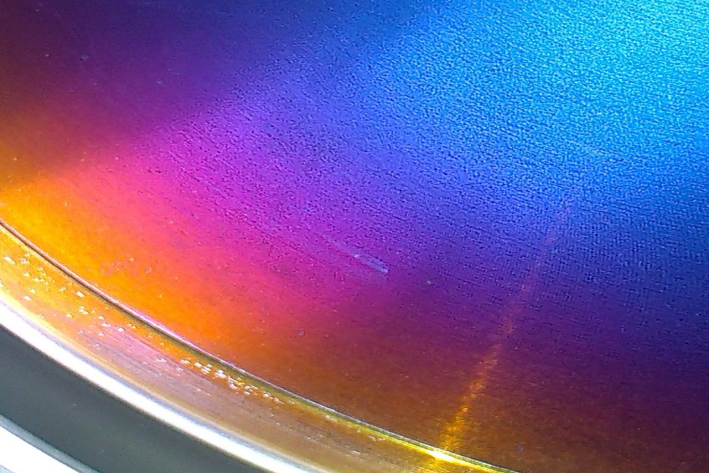

Rotatable Magnetron

The customized drop-in process lid is a complete package of dual rotatable magnetrons (DRM) consisting of magnet bars, end blocks, integrated anodes, power connections etc. The plug-and-play drop-in solution offers hardware integration into your existing coater.

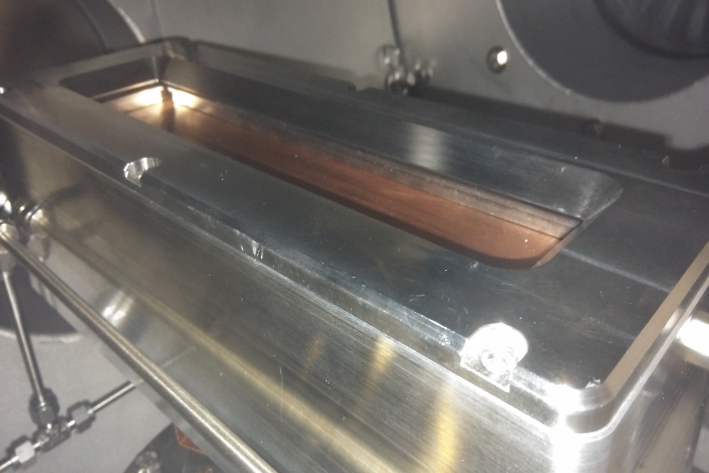

Planar Magnetron - Linear

Solayer's linear planar magnetrons include single and dual sputter sources to achieve very high target utilization. The membrane-free design with smart sealing techniques ensure no leakage of water. Solayer's proprietary IN-DRY® solution enables high performance of magnet arrays.

Process Monitoring & Control

The process monitoring and control system provides real time, in-situ control of vacuum and plasma-enhanced deposition processes. It is based on high-speed broadband spectrometers. The multi-channel unit controls reactive processes, achieves long term stability and secures process reproducibility.

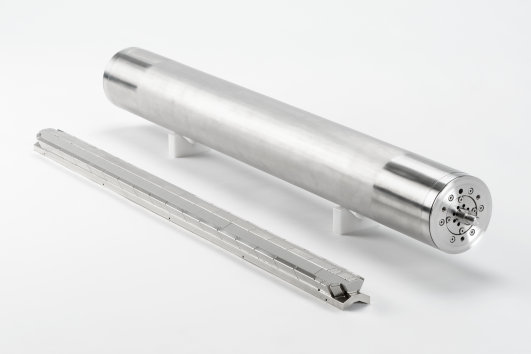

Magnet Bar

The high magnetic field strength magnet bar for rotatable magnetrons is based on Solayer proprietary IN-DRY® encapsulated magnets in a stainless steel jacket tube. The position-adjustable rotatable component is configurable for end blocks of different vendors.

Planar Magnetron - Circular

The circular DC magnetron is a customized sputter source with variable target sizes (starting from 1") for different thin-film deposition applications. With co-sputtering arrangement, several magnetrons can be adjusted in different angles through vacuum feedthrough.

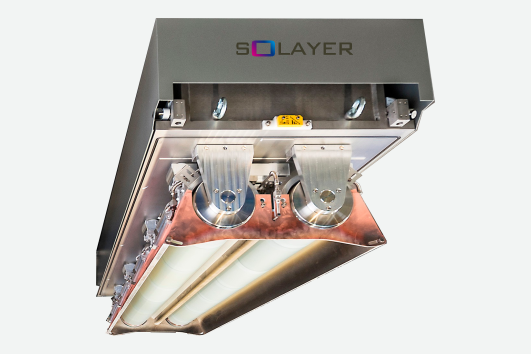

FLA Module

The FLA modules anneal glass / flexible substrates in inline or roll-to-roll production equipment. The water-cooled lamp and reflector arrangement can be easily integrated to flanges in process environments of various atmospheric environments (e.g. vacuum, glove box).

End Block

The horizontal or vertical-mount End Block for rotatable magnetrons is an easy retrofit for standard targets from all vendors. The compact design of the end block allows longer target material length with extended uniformity area within the same coater width.

Ion Source

The linear and circular ion sources are ideal components for substrate cleaning, etching and ion treatment for PVD/ PECVD. Our two variants, inductively coupled and capacitively coupled ion sources, generate plasma at work pressures and enable ion neutralization.

Sputter Targets

Solayer's portfolio includes rotary, linear and circular planar sputter targets of very high quality. The vast range of metallic, ceramic and inorganic targets are bonded and optionally assembled with backing plates. The targets are made in standard and custom sizes as per client requirements.

Lowest maintenance cost